EIP Ground Truth

ESP32-P4 EtherNet/IP adapter with IMU ground-truth for counterbalance

Status: This project is a proof-of-concept implementation and requires further development, testing, and validation before production use.

Overview

A comprehensive EtherNet/IP communication adapter for the ESP32-P4 microcontroller, integrating sensor support, Modbus TCP, and web-based configuration. The device serves as a bridge between EtherNet/IP networks and local I/O, sensors, and other industrial automation components.

This project implements a full-featured EtherNet/IP adapter device on the ESP32-P4 platform using the OpENer open-source EtherNet/IP stack. The device provides IMU-based ground-truth measurements for counterbalance applications, calculating roll, pitch, ground angle, and opposed-cylinder pressures.

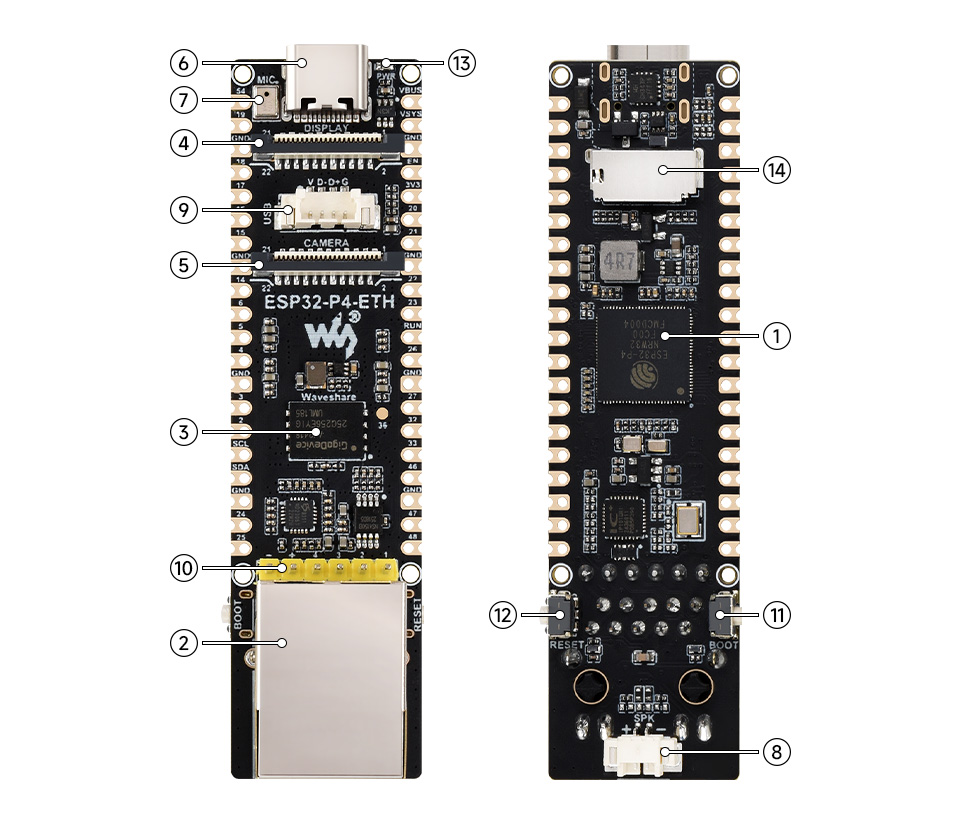

Hardware Platform

This project targets ESP32-P4 with Ethernet connectivity:

- Microcontroller: ESP32-P4 (Espressif)

- Ethernet PHY: IP101 (or compatible)

- I2C Devices: Optional IMU sensor (MPU6050 or LSM6DS3)

- GPIO Configuration: Ethernet: MDC, MDIO, PHY Reset (configurable); I2C: SDA, SCL (configurable, defaults GPIO7/GPIO8)

IMU Integration

The device supports 6-axis motion sensor support with automatic fallback:

- MPU6050: Primary sensor - Accelerometer-based orientation calculation

- LSM6DS3: Fallback sensor - Sensor fusion (complementary filter) combining accelerometer and gyroscope for accurate orientation

IMU Capabilities

Both sensors provide the following measurements:

- Roll and Pitch: Orientation angles from horizontal (degrees)

- Ground Angle: Angle from vertical (degrees)

- Cylinder Pressures: Calculated pressures for two opposed cylinders based on orientation, tool weight, tip force, and cylinder bore

Calculation Precision

All sensor calculations use 32-bit float precision (IEEE 754 single precision):

- Ground angle calculation:

acos(cos(roll) × cos(pitch))for both MPU6050 and LSM6DS3 (correct 3D angle formula) - Typical accuracy: ±0.04° for ground angle calculations (sufficient for industrial sensor applications)

- Values are scaled by 10000 for angles and 1000 for pressures when stored in assembly data

EtherNet/IP Assembly Structure

The device exposes three EtherNet/IP assembly instances:

Input Assembly (Instance 100) - 32 Bytes

Contains IMU sensor data and other input data:

| Offset | Size | Field Name | Description |

|---|---|---|---|

| 0-3 | 4 | DINT 0 | Roll angle (degrees × 10000) |

| 4-7 | 4 | DINT 1 | Pitch angle (degrees × 10000) |

| 8-11 | 4 | DINT 2 | Ground angle from vertical (degrees × 10000) |

| 12-15 | 4 | DINT 3 | Bottom cylinder pressure (PSI × 1000) |

| 16-19 | 4 | DINT 4 | Top cylinder pressure (PSI × 1000) |

| 20-31 | 12 | Reserved | Available space for other sensor data |

Note: Byte offset is configurable (0-12) to avoid conflicts with other sensors.

Output Assembly (Instance 150) - 32 Bytes

Contains control commands and configuration parameters:

- Byte 29: Cylinder bore diameter (scaled by 100: 0.01-2.55 inches)

- Byte 30: Tool weight (0-255 lbs)

- Byte 31: Tip force (0-255 lbs)

- Bytes 0-28: Control commands and other output data

Configuration Assembly (Instance 151) - 10 Bytes

A 10-byte configuration assembly is available for device-specific configuration parameters.

Modbus TCP Server

Standard Modbus TCP/IP server (port 502) provides additional protocol access:

- Input Registers 0-15: Map to Input Assembly 100 (32 bytes = 16 registers)

- Holding Registers 100-115: Map to Output Assembly 150 (32 bytes = 16 registers)

- Holding Registers 150-154: Map to Configuration Assembly 151 (10 bytes = 5 registers)

All assembly data is stored in little-endian format (Modbus converts to big-endian for transmission).

Network Configuration

The device includes RFC 5227 compliant Address Conflict Detection (ACD):

- RFC 5227 compliant static IP assignment (implemented in application layer)

- ACD probe sequence runs before IP assignment (deferred assignment)

- Natural ACD state machine flow

- EtherNet/IP conflict reporting in TCP/IP Interface Object Attribute #11

- User LED indication (GPIO27): blinks during normal operation, solid on ACD conflict

Web-Based Configuration Interface

Essential device management via web interface:

- Network Configuration: Set IP address, netmask, gateway, DNS (DHCP/Static IP modes)

- Firmware Updates: Upload firmware updates via web browser (OTA)

- REST API: All other device configuration, monitoring, and status information available via REST API

Access the web interface at http://<device-ip>/ after the device has obtained an IP address.

Sensor Configuration

Configuration via web API:

- Enable/disable sensor

- Configure byte offset (0-12) to avoid conflicts with other sensors

- View real-time readings (roll, pitch, ground angle, pressures)

- Calibrate sensor (LSM6DS3 only)

The device automatically detects and uses MPU6050 if available, otherwise falls back to LSM6DS3.

Software Requirements

- ESP-IDF: Version 5.5.1 or compatible

- Python: 3.x (for build scripts)

- CMake: 3.16 or higher

Connection Types

The device supports standard EtherNet/IP connection types:

- Exclusive Owner: Bidirectional I/O connection

- Input Only: Unidirectional input connection

- Listen Only: Unidirectional input connection (multicast)